Easy positioning

Precise positioning on the surface of the test object and high degree of stability when taking measurements

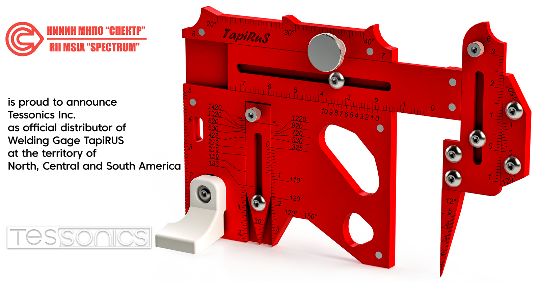

●Developed at the Scientific Research Institute of Introscopy (NIIIN MNPO "Spectrum") with the intention to replace the numerous patterns and devices used in visual inspection and conducting quality control of welded joints.

●The welding gauge allows you to measure most of the geometric parameters of welded joints and surface discontinuities such as the angle of bevel, angular misalignments of the edges, surface cracks, chipping marks, grinding marks, cavities and so on

●Equipped with the vital components which are used when positioning it on curved surfaces

●To carry out high-precision measurements, TapiRUS surfaces are marked with rulers, nonuses, markings and scales.

●It consists of measuring scales meant for measuring smoothness transition ,leg lengths, radius and bevel angles

●It consists of a taper gauge mounted on the High-Lo arm for measuring sizes the root gaps, the height/depths of the undercuts and angular misalignments